Specifying Cedar Decking

SPECIFYING

CEDAR DECKING

A deck made with Western Red Cedar, one of the

world’s most beautiful woods, is apt to be one of

the best looking decks in the neighborhood. But

Western Red Cedar decks have much more going

for them than good looks alone. Extending living

space to the outdoors, integrating home and land-

scape, making use of damp or uneven terrain and

giving a contemporary look to a traditionally-styled

home are just a few of the ways that decks make

life a little better.

Once the decision is made to build a deck, the

choice of decking material is just as important as

good design and quality construction. In today’s

environmentally conscious society, the natural

choice is Western Red Cedar.

All wood used in the outdoors must be protected

against decay and insect attack.Not only is Western

Red Cedar one of the few woods with its own

preservative oils, its freedom from pitch and resin

makes it an excellent base for protective coatings.

And cedar has other natural qualities that make it

the best choice for decking. It is the most stable of

British Columbia’s softwoods,so Western Red Cedar

decks stay flat and straight and resist checking.

Western Red Cedar decks are firm but resilient

underfoot, not hard and unyielding. The wood is

light weight, easily worked and ideal for almost all

types of finishes. It has an elegance that comple-

ments any architectural style and a beauty that

blends into all landscapes.

Whatever the reasons for building a deck, there is

just one natural choice of decking material.

Available in a wide range of grades and sizes, and

price-competitive with lesser materials, Western

Red Cedar decks are the beautiful, practical, long-

lasting complement to any home.

2

SPECIFYING WESTERN RED CEDAR

DECKING

To simplify specification, decking is now available in four

grade categories offered exclusively by members of the

Western Red Cedar Lumber Association.These few easily

understood categories of decking provide a choice of

quality clear grades or rustic knotty grades for outdoor

decks of any style and budget.

The following information is required when specifying

decking:

Specification Information Sample

Required Specification

Species:

Western Red Cedar WRCLA Western

Red Cedar

Size:

Specify the size 5/4 x 6

of decking.

Grade:

The grade of decking WRCLA Custom Clear

®

governs its overall quality.

Refer to following pages for

available grades.

Moisture Content:

Specify whether the Unseasoned

product is to be

seasoned on unseasoned.

Quantity:

Express in linear feet. 1000

Western

Red Cedar

DECKS

3

4

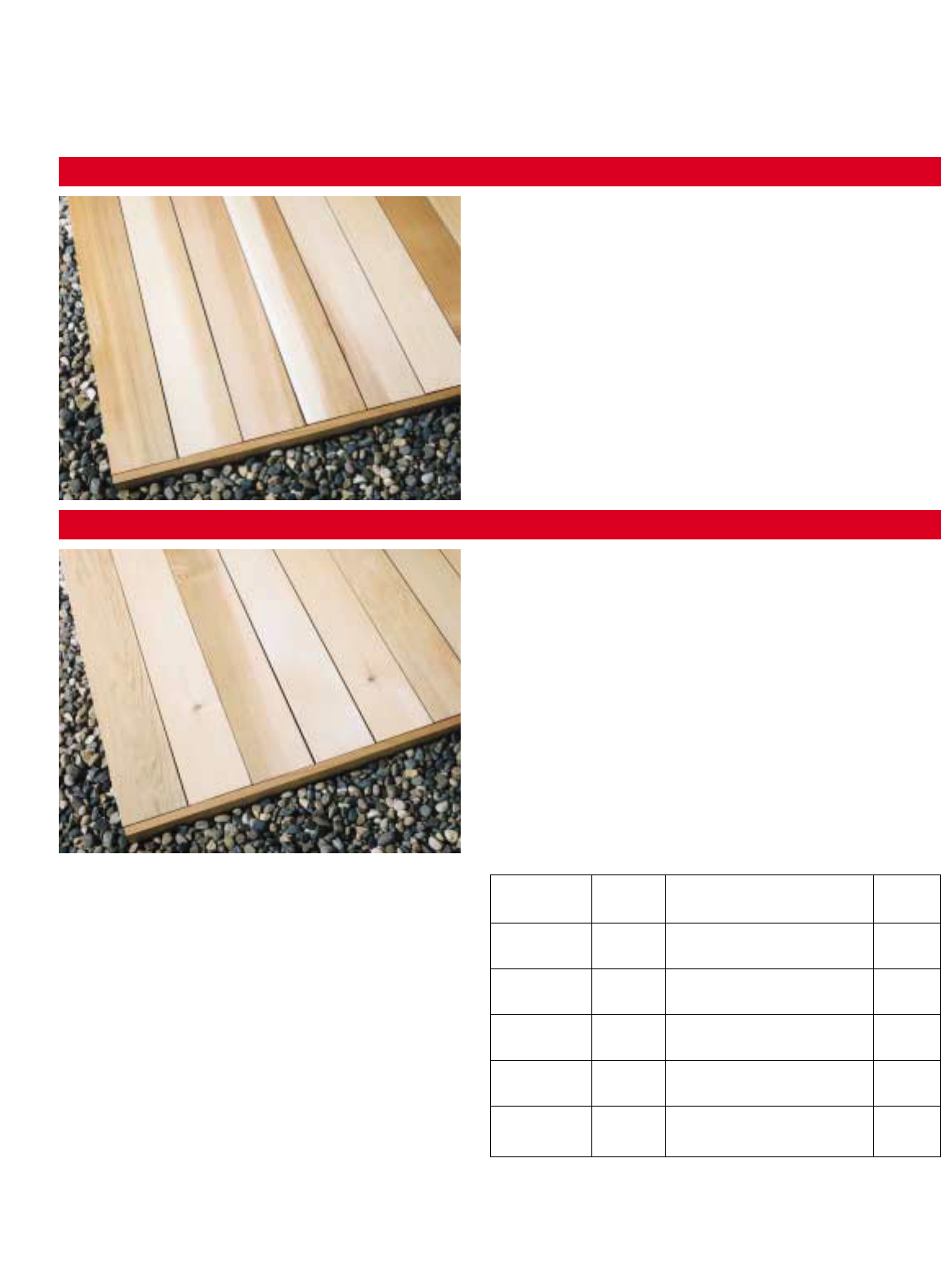

CLEAR GRADES OF WRCLA WESTERN RED CEDAR DECKING

Grade Description

The ultimate in durability and

appearance.Its fine grained

heartwood appearance will meet

the needs of the most demanding

clients.All aspects of

manufacturing and quality

control are performed to the

highest standards of the lumber

industry.Architect Clear decking

should be specified when only

the best will suffice.This

exclusive product is usually

manufactured to individual order.

Available seasoned or

unseasoned.

A quality product that combines

the stability and durability of

Western Red Cedar with a

sophisticated clear appearance

that will please the most

discriminating taste.Its finely

machined surface shows limited

characteristics which do not

detract from its natural good

looks.Custom Clear decking can

be used directly on the job and is

a natural for custom residences

and other applications where fine

woodwork is desired.Available

seasoned or unseasoned.

Thickness Width Span

(in.) (in.)

Grade Category

(in.)

1-1/4 4

All clear grade

16

categories

1-1/4 4

All knotty grade

12

categories

1-1/4 6

All clear and knotty

16

grade categories

24

All clear and knotty

24

grade categories

26

All clear and knotty

24

grade categories

Architect Clear

®

Custom Clear

®

SIZES AND SPANS OF WESTERN RED

CEDAR DECKING

WRCLA Western Red Cedar decking is available in a selec-

tion of thicknesses, widths and lengths as shown in the

table opposite.

Maximum spans for decking shown in the table are based

on a continuous beam with two equal spans and a con-

centrated load of 220 lb at the center of one span (see

illustration on page 5).The true span of the decking board

is used, taking into account the thickness of the support-

ing joist beneath it. Wet end-use conditions and unsea-

soned (green) lumber sizes are assumed.

5

KNOTTY GRADES OF WRCLA WESTERN RED CEDAR DECKING

Grade Description

Rustic charm at its best.Durable,

well manufactured Western Red

Cedar decking that comes ready

to use.This sound and tight-

knotted decking limits both the

size and quality of characteristics

to meet the highest buyer

expectations.The smooth,skip-

free dressing over the entire face

makes it the ideal deck surface.

The top choice where the natural

beauty and lasting charm of a

knotty deck are desired.Available

seasoned or unseasoned.

Widely used by homeowners and

builders,this category of knotty

decking combines the high

manufacturing standards required

for deckboards with a hole-free

knotty appearance.This category

limits the size and quality of

characteristics to provide an

economical and enjoyable knotty

deck.Custom Knotty decking

may be applied as received and is

a natural choice for home deck

builders,residential builders,and

commercial applications where a

durable knotty material is desired.

Available unseasoned only.

To help figure the amount of decking needed for a project, use

the following linear footage calculator:

To Cover 100 Square Feet of Deck

Nominal Size (in.) Linear Feet

1-1/4 x 4 325

2 x 4 325

1-1/4 x 6 211

2 x 6 211

Architect Knotty

®

Custom Knotty

®

Span

Span

Continuous Beam

Over Two Spans

220lb

Concentrated

Load at Centre

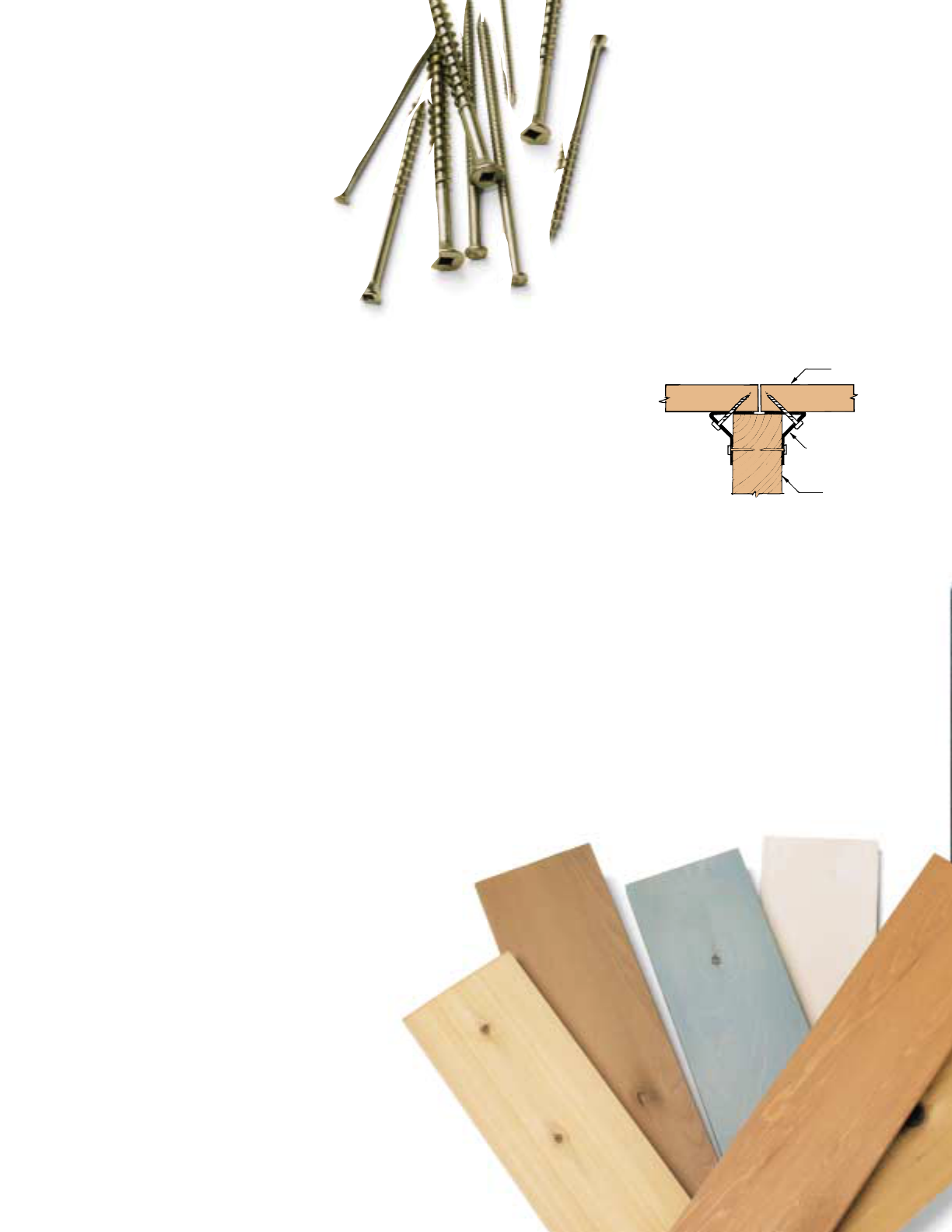

FASTENERS

Nails

Hot-dipped galvanized, aluminum and stain-

less steel nails are all corrosion-resistant

and all can be used to nail Western Red

Cedar.Other types of nails,such as elec-

tro-plated, are not recommended.They

can rust and disintegrate and react

adversely with the natural preservative oils

present in cedar, resulting in stains and

streaks. Copper nails also react with cedar

and should not be used.

Stainless steel is the best choice but hot-

dipped galvanized is the most widely used and economical.

Use 3 in. (10d) nails to fasten decking with a nominal thick-

ness of 2 in.and 2-1/2 in. (8d) nails on decking with nominal

thickness of 1-1/4 in.This will allow for nail penetration of

approximately 1-1/2 in. into deck joists for secure, trouble-

free construction (length may be reduced by 1/4 in.if ring or

spiral shank nails are used).Deck boards 2 in.wide need one

nail per joist while 4 in. and wider decking requires two per

joist.To prevent wood from splitting, use thin shanked nails

with blunt points.

Screws

Screws can also be used to fasten decks.

Double hot-dipped galvanized screws can

be used, however, stainless steel screws are

recommended. For most applications a 304

(18-8) grade provides adequate corrosion

resistance. For decks exposed to salt air,

use 316 grade. Screws must be long enough

to penetrate 1 in. into support members.

Penetration of 1-1/2 in. is required for structural

components.

Blind Fastening

Systems

These systems create

a fastener-free deck

surface.They employ

metal clips and/or

joist top brackets that

fasten the sides or

bottom of the deck

board to the joists so

that no fasteners are

visible.

6

FINISHING

Although cedar is naturally durable, a surface coat is recom-

mended to protect the wood and extend its service life.

Cedar accepts a wide range of stains and other coatings

and whichever is selected should be a good quality product

recommended by a paint or building supply dealer. When

selecting a finish coat, make sure it contains the following:

Water repellent

Fungicide/mildewcide

Protection against ultra violet (UV) light

Penetrating oil-based products, particularly those containing

pigments, are recommended for cedar. Pigments provide

increased UV protection. Note that decks require products

specifically formulated to withstand the abrasive effects of

foot traffic. Use of varnishes or other types of film forming

coatings are not recommended for cedar decks.These coat-

ings can crack and peel and once applied are difficult

to remove. Also, avoid non-drying coats as these

often feel sticky underfoot and can result in

stains on interior floor coverings.

BUILDING AND MAINTENANCE

TIPS

Space deck boards apart to allow proper

water drainage.A deck that dries after

wetting will last longer than one that

stays damp.

Keep the deck free of leaf, pine needle and other debris

build-ups.These can retain water and clog drainage channels

resulting in a deck that cannot drain and dry properly after

wetting.

Moisture and debris can collect where butt joints occur

over joists.To create drainage, butt decking boards between

double joists as shown, leaving a 1/8 in. space between the

ends of the boards.

Move planters, benches and other deck accessories

from time to time to allow the deck under them to dry

thoroughly.

Deck Board

Joist

Full Length

Fastener

7

The Western Red Cedar Lumber Association (WRCLA)

does not warrant the accuracy of the information herein.

The WRCLA,its directors,officers,employees,servants and

agents shall not be responsible or liable for any cause of

action, loss, damage, injury or death in any way connected

with the information herein even though such cause of

action, loss, damage, injury or death arises from the negli-

gence or default of the WRCLA, its directors, officers,

employees, servants or agents.

Wester

T

he Western Red Cedar Lumber Association (WRCLA)

is a non-profit trade association representing quality

producers of Western Red Cedar lumber products in

British Columbia, Canada and the US Pacific Northwest

states. Association members are dedicated to producing

quality sidings, decking, paneling, outdoor and other

specialty cedar products in a wide range of sizes and

grades. The WRCLA is committed to providing the

construction industry with information about WRCLA

member products,their specification, and proper use.

Distributed by: Bear Creek Lumber

Printed in Canada

Copyright 1993

93-494 Revised May 2000